1. Overview

GGD AC low-voltage distribution cabinet is a new type of low-voltage distribution cabinet jointly designed based on the requirements of the former competent department of DOE, power consumers and design department in line with the safe, economical, reasonable and reliable principles, widely used in distribution systems with the AC 50Hz, rated working voltage of 380 V, rated current up to 3150 A in power plants, substations, industrial enterprises and other power consumers as power, lighting and energy conversion, distribution and control in power distribution equipment.

2. Features

It features safe, economical, reasonable and reliable characteristics, widely used in power plants, substations, industrial and mining enterprises, mining, railway stations, hospitals, and other places, with high breaking capacity, dynamic thermal stability, flexible electric scheme, convenient combination, availability of series products and practicality, original in structure; rated current can be increased to 3150A, suitable for distribution transformer below 2000kVA; domestic electrical components of mass production with process stability have been used in the cabinet, imported components can also be installed; HD13BX and HS13BX rotary knife switch is specifically designed to meet the needs of unique structure of GGD cabinet, which changes the operation mode of the mechanism, meanwhile retaining the advantages of the traditional product, it is a utility-type electrical components; bus clip made from high-strength and flame-retarded PPO alloy material after thermoplastic molding, with high dielectric strength and self-extinguishing properties; 8MF cold-formed steel frame assembled with local welding; the finish paint of the cabinet uses electrostatic epoxy powder coating, with strong adhesion and good texture, orange-peel in international gray; protection class of the cabinet is IP30, the user can also choose between IP30-IP40 in accordance with service conditions.

3. Normal service conditions

a. surrounding air temperature does not exceed +40 ℃, nor lower than -5 ℃, the average temperature within 24h shall not exceed +35 ℃;

b. indoor installation, the altitude of installation place shall not exceed 2000M;

c. the relative humidity of ambient air at the highest temperature of +40 ℃ shall be less than 50%, and a higher relative humidity is allowed at a lower temperature, (for example, 90% at +20 ℃) taking into account the condensation on the product surface due to temperature changes;

d. the vertical gradient of the equipment when installed is not more than 5%;

e. the equipment should be installed in areas without severe vibration and its electrical components are free from corrosion; users with special requirements can consult with the manufacturer for solution.

4. Standards

GB 7251.1 Low-voltage switchgear and control equipment: part 1- type test and partially type-tested low-voltage switchgear assembly;

IEC60439-1 low-voltage switchgear and control equipment components: part 1- type-tested and partially type-tested assemblies;

IEC60529 Degrees of protection provided by enclosure and appropriate standards.

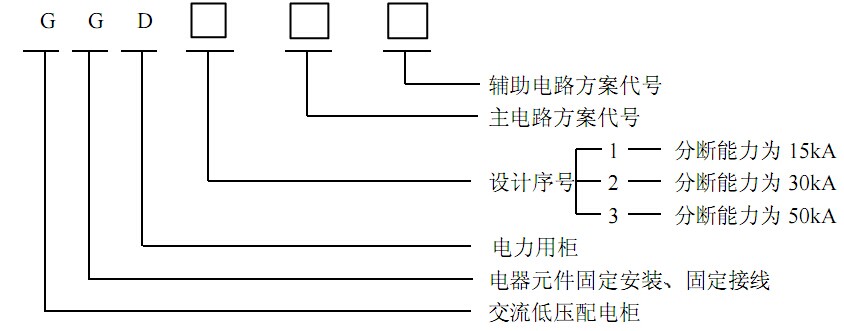

5. Model structure and implications

7. Product structure

a. The enclosure of GGD AC low-voltage distribution cabinet is in the general-purpose form, cold-formed steel frame assembled with 8MF local welding, supporting parts and special parts for the frame are supplied by section steel manufacturing plant to ensure the accuracy and quality of the cabinet.

b. general-purpose cabinet components designed by module, with 20-module mounting holes and high general-purpose coefficient.

c. GGD cabinet designed to take full account of heat-dissipation problem when the cabinet is running, with different number of heat-dissipation slots in the upper and lower ends of the cabinet, when the electrical components inside the cabinet are heated, the heat rising and discharged through the slot at the upper end, and cold air constantly flows into the cabinet from the slot at the lower end, thus the sealed cabinet has formed a bottom-up natural ventilation channel for heat dissipation.

d. GGD cabinet designed in accordance with the requirements of modern industrial product design, the method of golden ratio is applied to design the cabinet shape and separate dimensions of various parts, so that the entire cabinet looks nice and novel.

e. The cabinet door is connected with the frame by a rotary active hinge, easy for installation and removal. The door flanging is embedded with a gable-type rubber strip, allowing for a certain compression stroke between the door and the frame when closing the door to prevent the direct collision of door with the cabinet, improving the level of protection.

f. Instrument mounted with electrical components is attached to the frame by multi-strand copper wire. Installation parts in the cabinet are connected to the frame with the knurled screw and the frame mounting connection, so the entire cabinet forms a complete ground fault protection circuit.

g. cabinet finish adopts polyester orange-shaped baking finish, with strong adhesion and good texture. The entire cabinet shows matte, avoiding the blinding effect, creating a comfortable visual environment for operator on duty.

h. cabinet protection class is IP30, the top cover of the cabinet can be removed when needed, convenient for assembling and adjusting the main bus on site, roof corners of the cabinet is provided with rings for lifting and loading